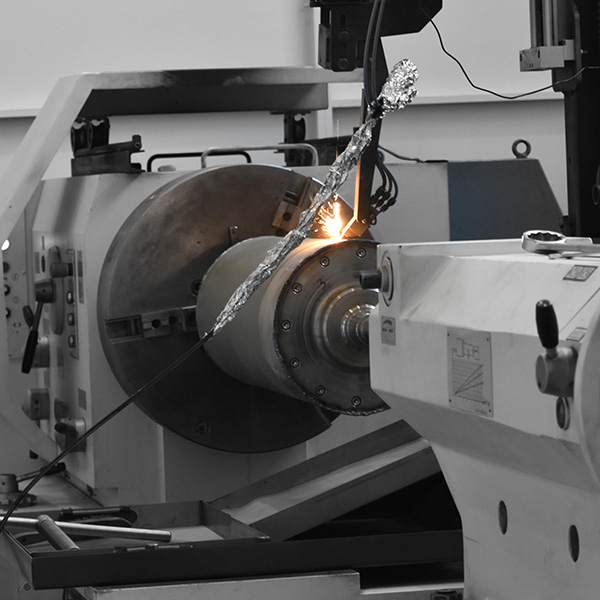

Laser cladding

Laser cladding is a process in which a powdered metal is steered in the direction of a metal surface by means of a gas propellant. The powder is fused with the base material using a laser. This process means that a low level of heat is created in the machine components, which results in the material properties of the different metals being fully preserved.

Laser cladding is ideal when repairing components or in the preventive treatment of various surfaces.

ADVANTAGES

- Less distortion

- Excellent adhesion due to metallic binding

- Wide range of powders to choose from

- Corrosion-resistant

- Hard-wearing

- Heat-resistant

- Non-porous

- Environmentally-friendly process

COATING OPTIONS

- 316L Si stainless steel

- One of the most commonly used stainless steels in the trade. Can be applied to almost all steel alloys and therefore highly suited for repairs.

- Duralloy

- The field of application is identical to that of 316L Si stainless steel, but it is harder and more wear-resistant. However, this version is not as corrosion-resistant.

- Stellite 6

- A super alloy that combines excellent corrosion resistance with an extremely good wear resistance up to 500°C.

- Wearalloy

- Alloy with excellent wear resistance.

- Hastelloy C276

- Suitable when the highest level of corrosion resistance is needed.

Many other coatings are possible.

Gearcraft nv

Kalkhoevestraat 32

8790 Waregem

Belgium

P +32 56 60 17 72

developed with the support of

Gearcraft nv

Kalkhoevestraat 32

8790 Waregem

Belgium

developed with the support of